Overview membrane systems

Membrane filtration isa mong the most innovative filtration techniques.

In addition to standard equipment for

- Microfiltration (MF)

- Ultrafiltration (UF)

with standard filtration elements on a polymer basis, we offer advanced process technology and proprietary membrane modules based on ceramic. The focus here is on modules with particularly high permeability and with very good chemical resistance.

A mobile container system is available for on-site testing. This makes it possible to find the best process technology even for tricky cases.

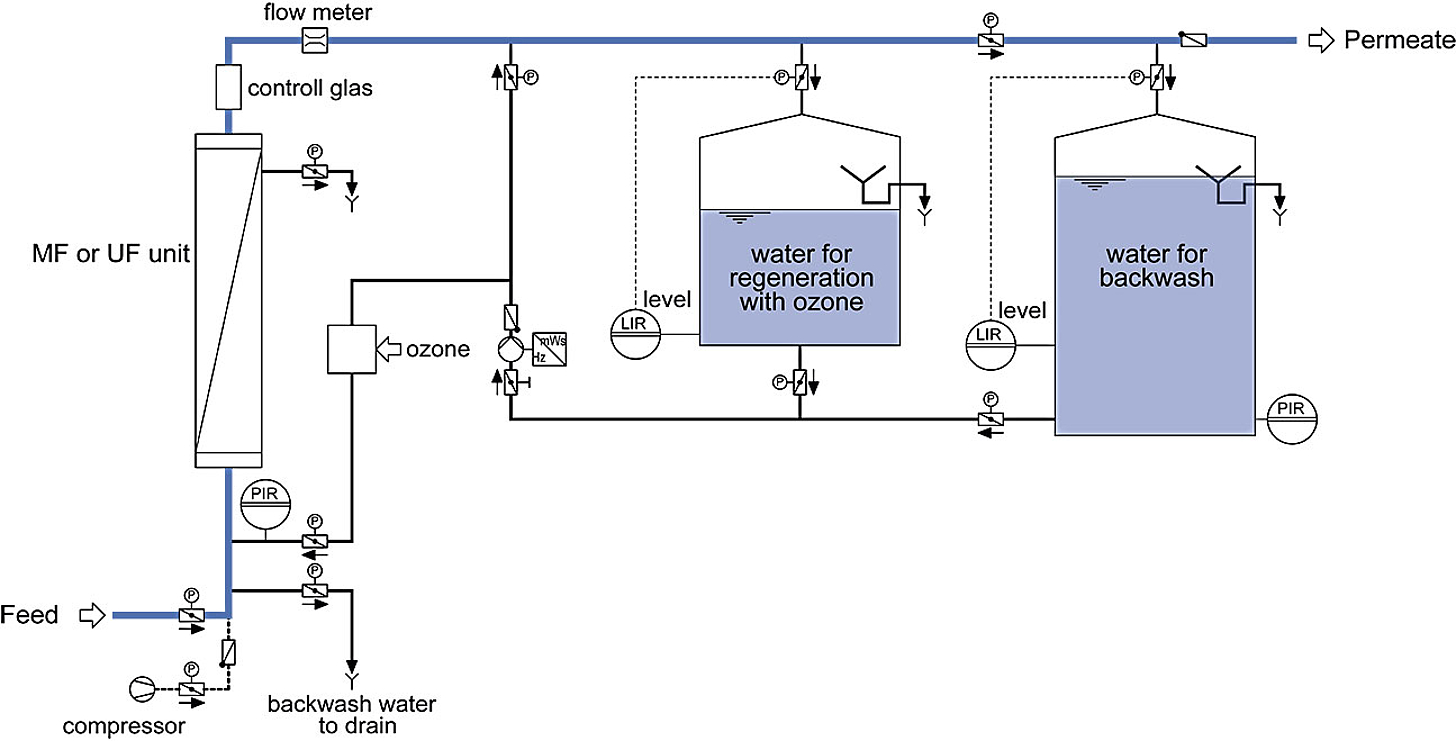

A special focus of our activities lies in the successful implementation of a chemical-free plant operation. The modules are regenerated by the use of ozone.

Membrane filtration with Ozone regeneration (Pat)

Filtration processes based on micro- or ultrafiltration are used in many areas for the treatment of water. A main problem with the membrane filtration is the so-called fouling. Fouling results in puddling and clogging of pores on the membrane, which leads to an increase in the pressure loss or a decrease in the filtration performance. Fouling can not be reversed by normal flushing procedures. For the removal of the fouling layers, more or less intensive chemical-oxidative cleanings are required, which requires a corresponding waste water aftertreatment (AOX formation).

By using ozone in front of the membrane, fouling can be avoided permanently if filtered with ozone-containing water. However, this operating state requires an activated carbon filter stage downstream of the membrane stage in order to completely reduce the residual ozone passing through the membrane in the water. Ultimately, however, a carbon filter is a source of germ, which is why a final disinfecting operation with e.g. Chlorine is required.

The HG-MFO method (Pat) solves this conflict permanently. Ozone is used here exclusively for the regeneration or for the prophylactic minimization of fouling layers in the closed circuit.