Rapid decarbonisation (RDC)

Rapid decarbonization is considered the most inexpensive and environmentally friendly process for centralised softening of drinking water - especially when softening large quantities of water.

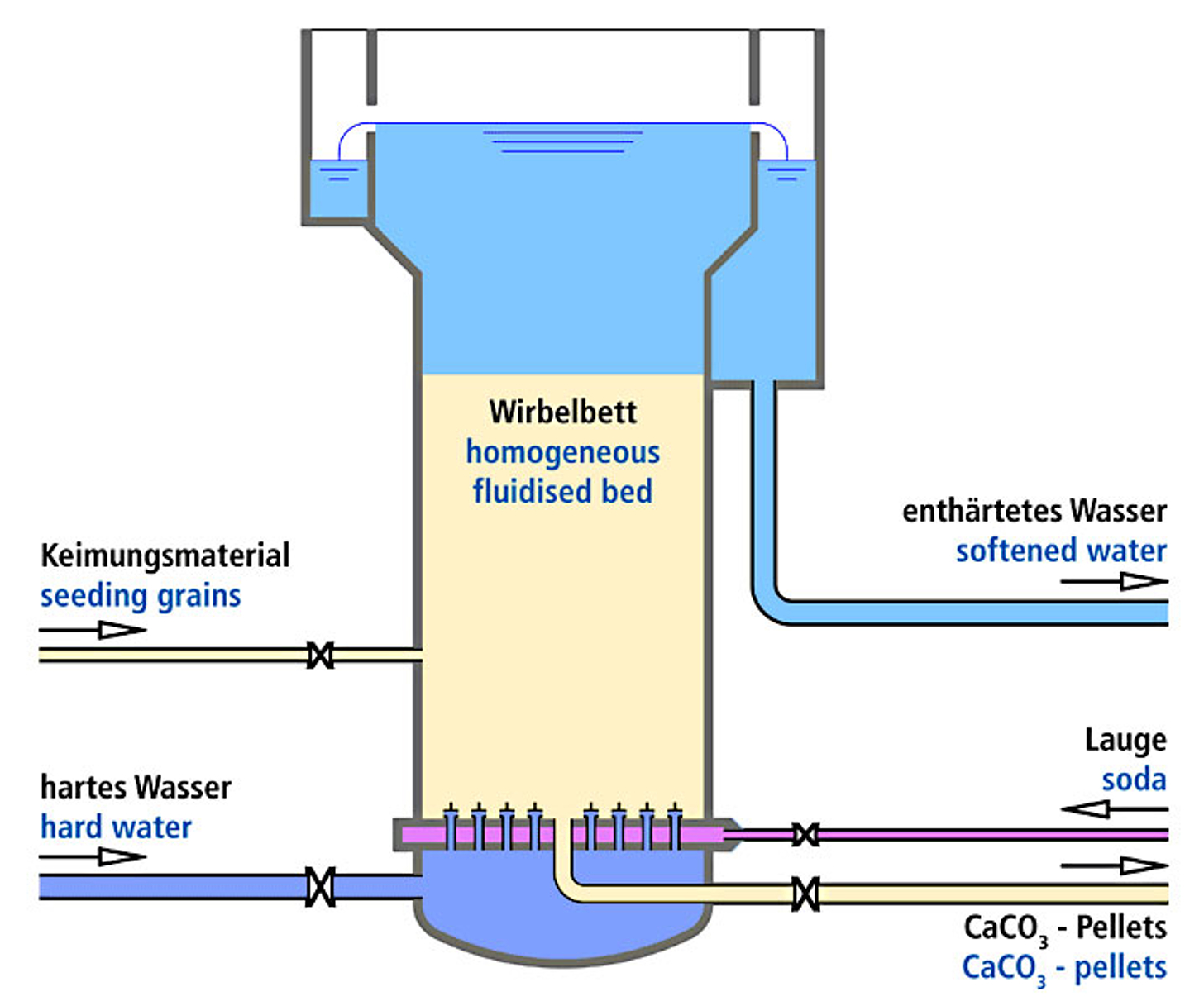

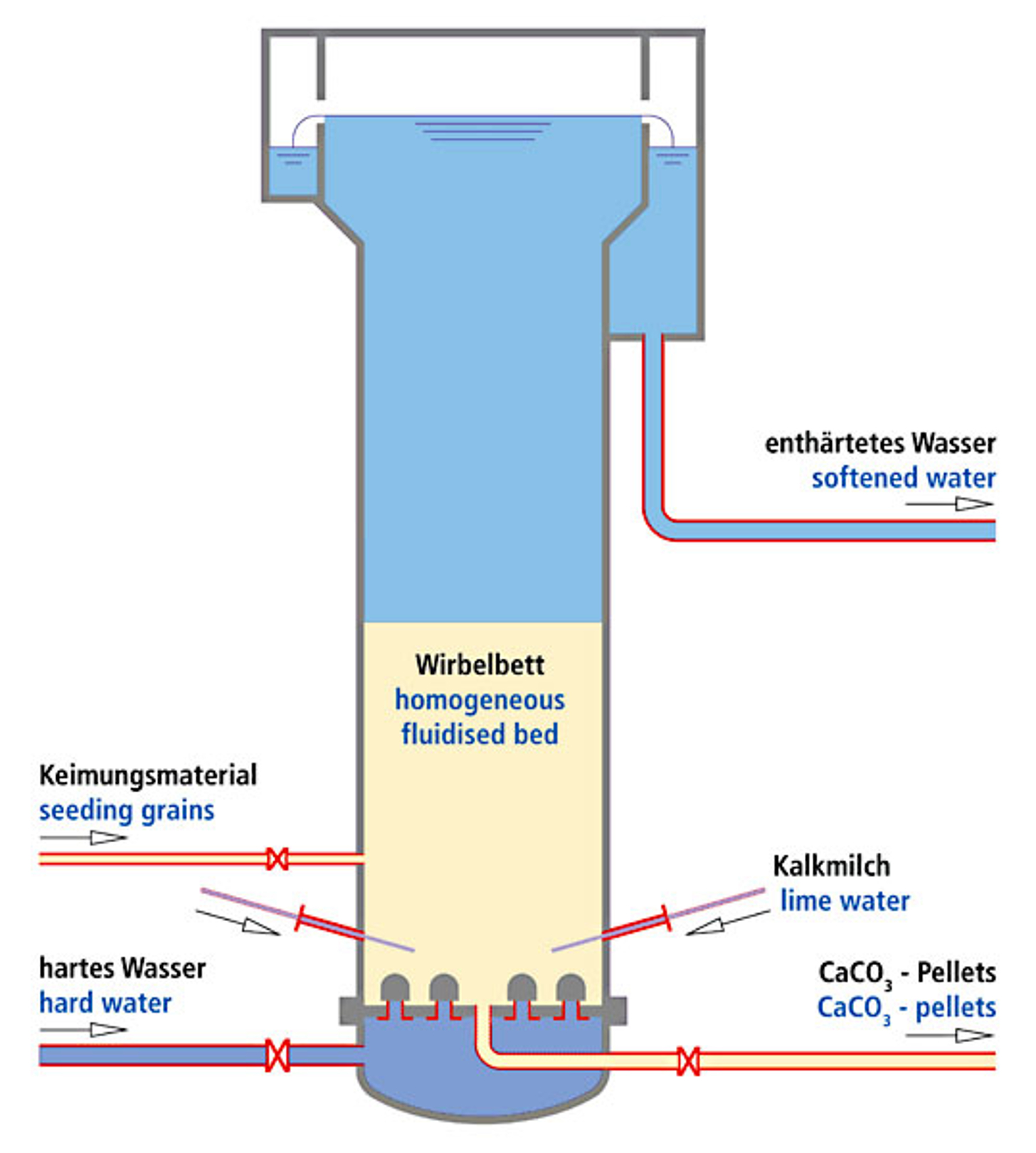

In rapid decarbonisation the lime is removed in a so-called fluidised bed reactor.

Advantages of softening in a fluidized bed

- Softening from hardness range 4 to 2

- Prevention or reduction of limescale deposits in hot water systems

- Lower energy consumption

- More pleasant and skin-friendly water

- Lower consumption of regeneration salts

- Lower consumption of detergents and cleaning agents

- Less waste water pollution

- Magnesium content remains constant

- Pellets for agricultural use

- Additional costs for end users: only 0,10-0,15 €uro/m3

The lime-carbonic acid balance is disturbed by the dosing of lye (depending on the raw water quality - caustic soda or lime milk) to such an extent that the lime precipitates and grows up to pellets at crystallisation germs. The pellets swim in the reactor that flows from bottom to top, grow up and are removed from the reactor from time to time. The systems operate fully automatically.

Rapid decarbonation with sodium hydroxide dosing

In the so-called "Amsterdam process" softening is carried in the fluidised bed reactor by dosing sodium hydroxide (NaOH). An extremely intensive mixing-in is achieved by means of special nozzles that causes the lime to precipitate spontaneously and grow into pellets. The sodium hydroxide increases the sodium contents of the water slightly.

Advantages of this process:

- The exit turbidity is extremely low

- As a rule no downstream filter stage is required

Rapid decarbonisation with lime milk dosing

In the newly developed process softening in the fluidised bed reactor is based on the dosing of lime milk (CaOH). Dosing is carried out here via dosing lances directly into the reactor inlet. Here too the lime grows into pellets. In lime milk dosing a filter system has to be located downstream for clarification.

Advantages of this process:

- Sodium contents of the water remains constant

- Less expensive than the Amsterdam process