Centralised softening of drinking water

The term "water hardness" primarily refers to the concentration of the alkaline earth metals magnesium (Mg) and calcium (Ca) dissolved in water. The higher their concentration, the harder the water.

When water containing carbonic acid reacts with carbonate rock (such as CaCO3 and MgCO3), the minerals dissolve to form bicarbonate (hydrogen Carbonate HCO3-). There is no legal limit for water hardness, even though it causes problematic limescale deposits and leads to increased consumption of detergents and cleaning agents.

How is water hardness defined?

According to the International System of Units (SI), the concentration of alkaline earth ions is expressed in mmol/L. Nevertheless, water hardness is still commonly reported in degrees of German hardness (°dH).

One degree of German hardness (1 °dH) is defined as 1 mg of CaO per 100 mL of water, corresponding to approximately 0.18 mmol/L of alkaline earth ions.

Classification of water hardness:

- Soft: ≤ 1.5 mmol/L (approx. ≤ 8.4 °dH)

- Medium: 1.5–2.5 mmol/L (approx. 8.4–14 °dH)

- Hard: ≥ 2.5 mmol/L (approx. ≥ 14 °dH)

Centralised softening of drinking water has been increasingly discussed and technically implemented in recent years, particularly in regions with high water hardness. Hardness levels above 3.5 mmol/L (≈ 19.6 °dH) can lead to increased limescale formation. The supply of water with hardness levels of 3 or 4 therefore often results in undesirable effects for consumers, such as:

- Increased cleaning effort for surfaces due to limescale deposits

- Significant increase in energy consumption in heat exchangers

- Increased detergent consumption

- Reduced service life of pipes and fittings

In some cases, elevated heavy metal emissions from drinking water installations are also environmentally relevant.

For this reason, many consumers opt for decentralised water softening systems, which typically operate on the principle of cation exchange. However, these systems incur considerable ongoing costs of around €0.80 to €1.00 per cubic metre of softened water (taking into account depreciation over ten years, salt consumption, and maintenance). In addition, water consumption increases due to the regeneration of the ion-exchange resins, and the wastewater is further burdened with regeneration salt.

Method for centralised water softening

The better way is centralised softening in the water work for which various processes are available:

- Slow decarbonisation (SDC)

- Rapid decarbonisation (RDC)

- CARIX process (ionexchange process)

- Nanofiltration process (NF) and

- Reverse osmosis (RO)

Relevant factors for the choice of the process are, in addition to the composition and the quantities of the contents, in particular also the pre-treatment, the treatment capacity, the recycling of the waste materials, the conditions for the discharge of the unavoidable waste water as well as any post-treatment that may be required.

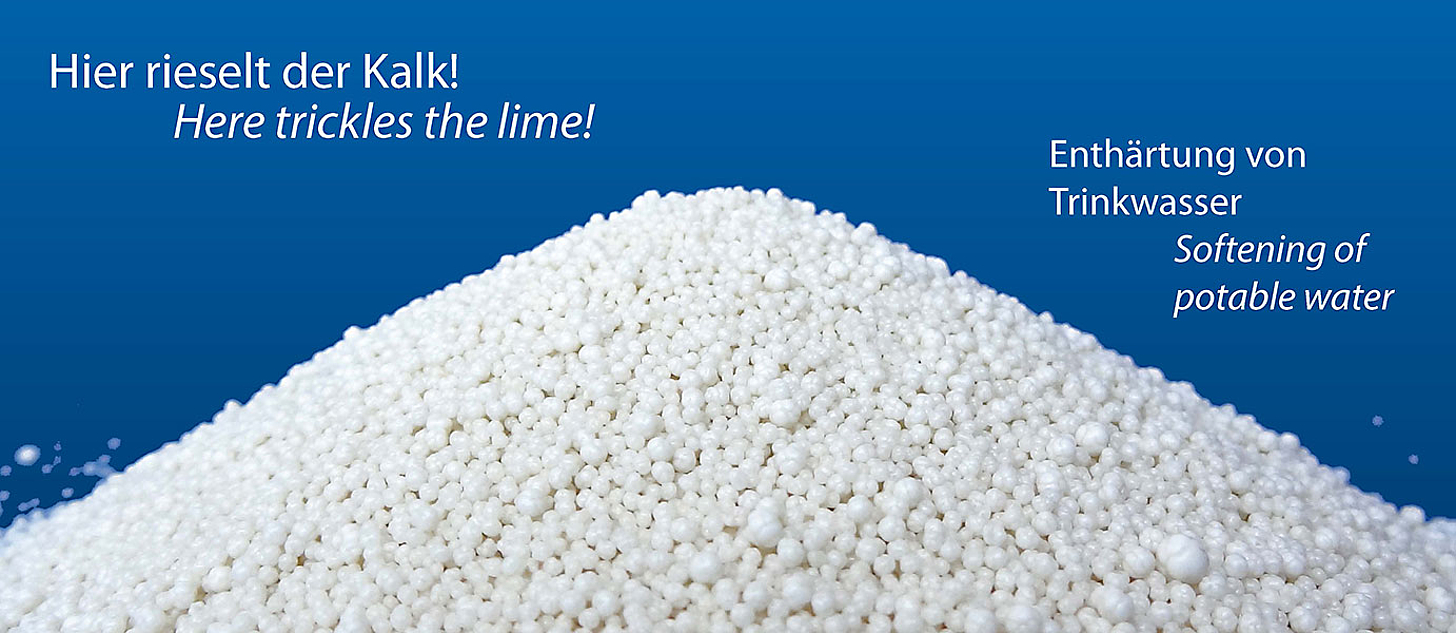

The picture above impressively shows how much lime can be dissolved in water. The pellets shown here come from a decalcification plant using the rapid decarbonisation process. The high-purity pellets can be used in the building materials industry or in agriculture as soil improvers.

HydroGroup is specialized in rapid decarbonization and innovative membrane technologies such as low pressure nanofiltration (LPRO) and reverse osmosis (RO).

Consulting and Planning

Are you interested? We would be pleased to support you in the design of your water treatment system and in selecting the optimal process. Please contact us.