The HydroSystemTower® is

- manufactured completely at the factory

- transported to the installation location

- mounted on the base provided by the user

- connected and commissioned.

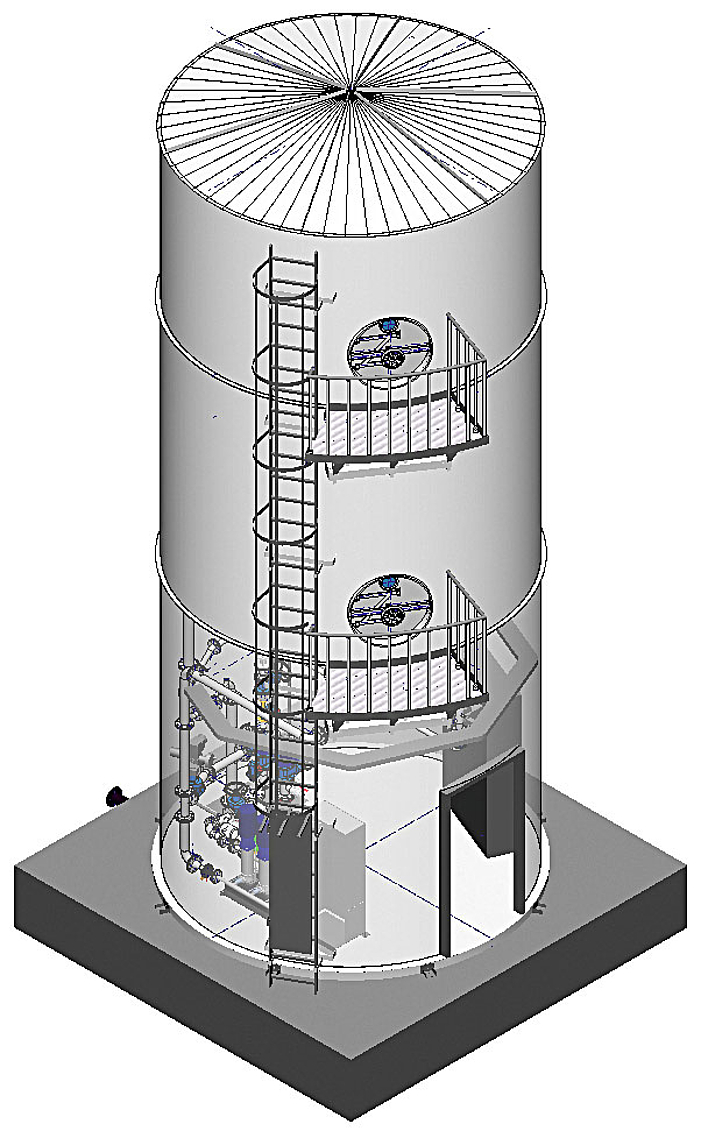

The lower section of the tank contains the installation room. This is where pipeline installation, pumps and pressure booster systems, water treatments systems and switchgear assemblies can be configured. Access to the installation room is gained via a secured and thermally insulated door. A room air dehumidifier with dew point sensor is installed to prevent condensation on the inner surfaces. The tower has thermal insulation and complete weather-proof panelling on the outside.

Advantages of the stainless steel water tower

• Use of stainless steel instead of concrete or plastic

• High level of hygiene, quality and safety

• Absolutely leak-tight, full system control

• Ventilation via microfilters

• Integrated installation room

• Thermal insulation with VA weather-proof panelling

• Compact, space-saving and cost-effective

• Extremely short construction site time thanks to factory manufacture

• Well thought-out right down to the very last detail

• Integrated tank cleaning system

• For volume of up to 150 m³ (single or dual-chamber)

Tank volume

- Nominal tank diameter 4.0 m (without insulation)

- Height up to 15 m

- Volume up to 150 m³ per tower,

multiple towers can be connected in parallel - Duplex steels ASTM S32101, S32205

- Custom versions on request

For additional information, please refer to the PDF file in the download area. The possible access and transport routes are variables which affect decision making and must be clarified in advance.

We will be happy to help you with project planning. Call us and we will work together to develop the best solution for you.

HydroSystemTower® is a registered trademark of Hydro-Elektrik GmbH