Water treatment processes

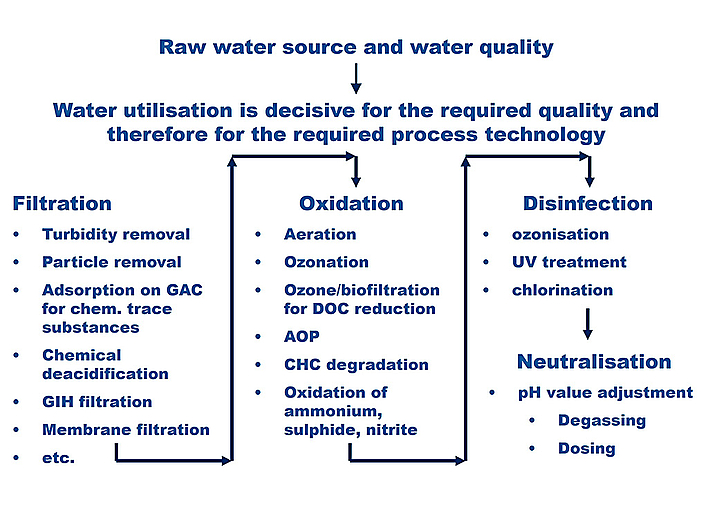

Water treatment includes a variety of processes that are specifically used to convert raw water (e.g. groundwater, surface water or wastewater) into water of a specific quality. Depending on the requirements (e.g. drinking water, process water, etc.) and the quality of the raw water, several water treatment processes are often combined.

The most important techniques used in this process are mechanical separation, chemical-physical water treatment, biological processes, as well as final disinfection. The planning of drinking water treatment plants is a complex process that requires a great deal of experience and expertise.

Each plant is designed individually. As an experienced system provider, we analyse the respective water quality, select the optimal process steps based on this and coordinate the systems with each other.

Together with our customers, we analyse their needs, plan the implementation and carry it out efficiently, including the necessary process control, automation and visualisation as well as proactive service.

HydroGroup – Technology That Inspires Trust

- Over 50 years of experience in treatment, energy, and control technologies

- Proven solutions for municipal and industrial water supply systems

- Customized consulting and planning tailored to your needs

- Robust technologies designed for continuous operation and the highest demands

- Partnership-based project management with a dedicated point of contact

Mechanical Processes for Substance Separation

These processes are primarily used to remove coarse or undissolved components such as solids and organic matter (e.g., aquatic animals):

- Rakes, screens, backwashable screen filters, and cartridge filters for retaining coarse materials

- Flotation for separating fine particles by attaching them to fine air bubbles, causing them to float

- Sedimentation for settling suspended solids by gravity (commonly used in backwash water treatment)

- Filtration – for removing particulate matter using, for example, sand filters, multi-layer filters, and similar systems

Chemical-Physical and Biological Processes

These processes modify water composition through chemical and physicochemical reactions:

- Precipitation and flocculation by dosing aluminum or iron salts (agglomeration)

- Aeration or oxygenation to oxidize iron and manganese

- Ozonation for disinfection and advanced oxidation – ideal for drinking water treatment

- Neutralization to adjust the pH value (e.g., via filtration through lime or CO₂ stripping)

- Ion exchange to remove hardness-forming components such as calcium (Ca²⁺) and magnesium (Mg²⁺)

- Adsorption to remove organic substances using activated carbon

- Central softening at water treatment plants to provide softer water

- Membrane processes, such as microfiltration, ultrafiltration, nanofiltration, or reverse osmosis, for highly efficient purification

- Ozone biofiltration, particularly effective for treating surface water containing humic substances