Ozone-Biofiltration

When preparing tea, a tea bag is placed in hot water. During the short steeping time, substances from the tea leaves are released into the water, changing its taste and colour. A similar process takes place in nature: decomposing organic material (e.g., grass clippings after a few days) releases high-molecular-weight organic compounds (humic substances), which dissolve in water and likewise lead to changes in taste and colour.

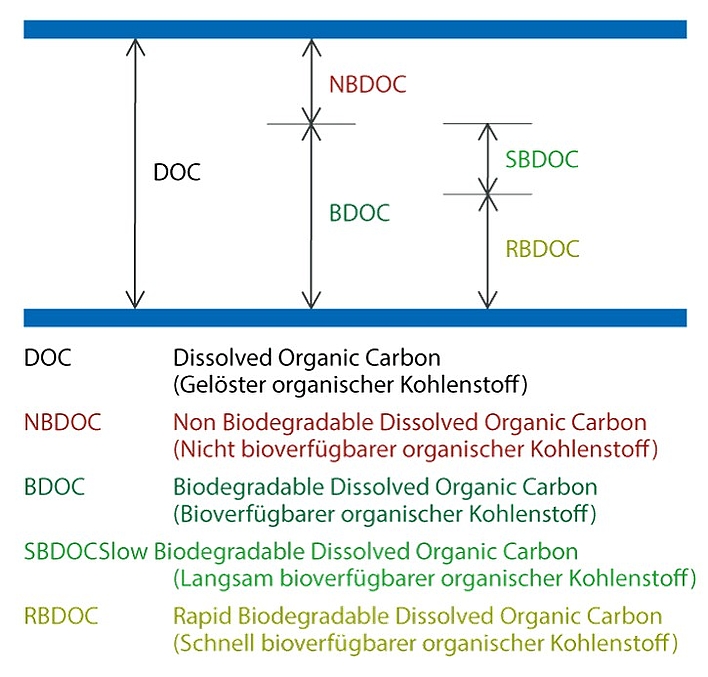

Humic compounds consist mainly of carbon, hydrogen and oxygen, with small amounts of nitrogen and sulphur. These natural organic substances (NOM = Natural Organic Matter) are analytically quantified using the sum parameters for organic carbon (TOC/DOC).

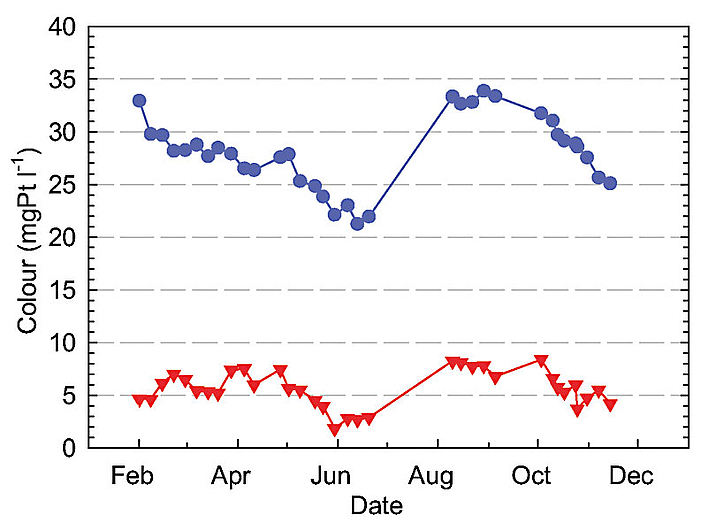

The chromophoric structures of humic substances absorb certain wavelengths of visible light, causing the characteristic yellowish to brownish discolouration of the water. Colour is measured as the spectral absorption coefficient at a wavelength of 436 nm (SAK436 or unfiltered SSK436). The limit value for drinking water colour is 0.5 m⁻¹. Internationally, the colour of water is measured using the platinum-cobalt scale (Pt-Co) (Hazen scale) and expressed in mg Pt/l.

Ozonation followed by biofiltration (ozone biofiltration) has proven to be an effective process for the targeted removal of colour and the reduction of DOC.

Principle of ozone biofiltration

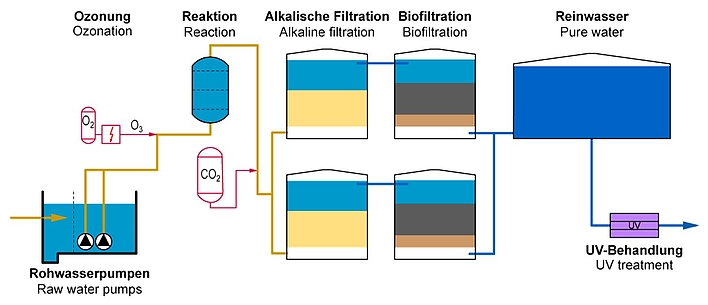

Ozone biofiltration is used specifically for decolourisation and for the treatment of water containing humic substances. The process is a multi-stage process based on natural mechanisms of action. The first stage is always ozonation, during which the water is simultaneously disinfected. In the case of very soft water, biofiltration is often preceded by a hardening stage. Biological mineralisation then takes place in the biofilter. Final hygienisation is usually achieved by UV treatment.

1st Stage ozonation

For optimum energy efficiency, the gaseous ozone must be dissolved as completely as possible in the water, and a sufficient reaction time must be ensured. Inorganic substances such as iron and manganese are oxidised very quickly. The high ozone doses and long residence times also ensure reliable disinfection.

In the reaction tank, the ozone concentration gradually decreases due to the reactions taking place. Long-chain dissolved organic carbon (DOC) compounds are split into low-molecular-weight fragments. Some of these degradation products are biologically available (BDOC) and are further degraded in the downstream biofiltration stage by microbiological processes. At the same time, changes in the chromophoric structures of the DOC lead to a significant reduction in colour.

2nd stage Alkaline filter

Water with very low hardness, i.e., without significant amounts of magnesium and calcium, is sensitive to pH changes. Moderate hardening stabilizes the water and enables effective flocculation processes.

Hardening is usually achieved by filtration through alkaline filter materials such as calcium carbonate (CaCO₃). Since the natural CO₂ content of the water is usually insufficient to specifically increase the hardness, a small amount of carbon dioxide (CO₂) is added to the raw water upstream of the filter. This reacts with the water to form carbonic acid (H₂CO₃), which in turn reacts with the calcium carbonate in the filter material, thereby increasing the water hardness.

3rd Biofilter

The biofilter is the heart of ozone biofiltration. Several important processes take place in it: First, excess ozone is completely broken down. At the same time, biologically available carbon (BDOC) is mineralized, oxidized inorganic substances are retained, and particles are separated. Optimal filter speeds are between 6 and 9 m/h. The selection of filter materials and their bulk heights depends on the water quality. Bulk heights of 3 m and more are quite common.

Drinking water treatment

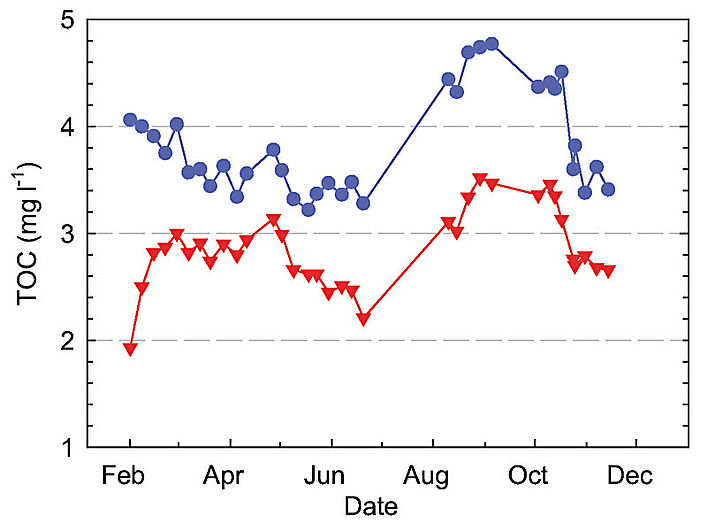

The natural organic matter (NOM) content is crucial when water is to be used for drinking water supply. Water with elevated DOC should not be used as drinking water without treatment. In water free of turbidity, the TOC is almost identical to the DOC. Even supposedly stable waters can be prone to contamination after oxidative treatment (e.g. addition of disinfectants).

The colour of the water depends on the DOC, but does not correlate directly with it: waters with low DOC can be strongly coloured, while waters with high DOC can have little colour. Ozonation breaks down colouring substances, reducing colouration by 80–95%.

The blue curves show raw water values, the red curves show purified water values.

Advantages of ozone biofiltration

One particular advantage of ozone biofiltration is its high environmental compatibility. In contrast to nanofiltration systems or reverse osmosis, practically no environmentally harmful substances need to be used. Chemical oxidation with ozone also breaks down any trace substances from pesticides or pharmaceuticals that may be present.

The single-stage process is not suitable for all types of water; in some cases, two-stage treatment may be necessary.

We would be happy to support you in planning your system with our extensive experience. In addition to the hydraulic values, a complete water analysis is essential for the planning process. You will find a questionnaire in the form of a checklist in the download area.

Talk to us!

Simply describe your requirements to us. We will support you

- with the technical evaluation

- the selection of the optimal process, and

- the design and dimensioning or

- the pilot testing with one of our containerised plants.

We will help you – professionally and practically.