Microbiological contamination can occur in natural water resources as well as during transport due to damage in the pipeline network and in reservoirs. In accordance with the relevant regulations, drinking water must always be of perfect hygienic quality and be durable. In order to guarantee this, various disinfection measures are used in the water supply system:

Chemical disinfection:

In chemical disinfection substances containing chlorine are usually dosed (chlorine dioxide, sodium and calcium hypochlorite solutions or chloric gas solutions). Chlorination is used either as a permanent addition for network protection or temporarily in the event of damage.

An excellent disinfection is also achieved when ozone is used. However, as a rule a filter stage for the decomposition of residual ozone and biological mineralisation is required. Ozone is not suitable for network protection.

Membrane technology:

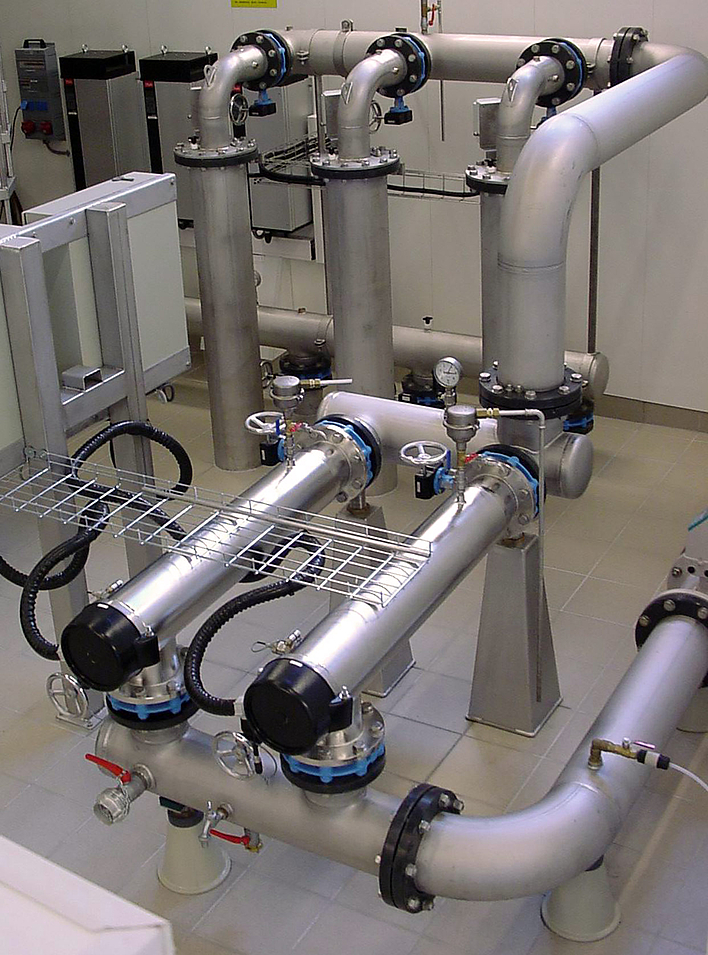

Microorganisms can be held back and removed from the water with membranes (pore size smaller than 0.2 µm). To be on the safe side, UV systems are usually installed after ultrafiltration systems.

Thermal disinfection:

Thermal disinfection is primarily used at boiling in households or in hot-water treatment systems for Legionella prevention.

UV disinfection:

The disinfection of water with UV light is a physical process. Under favourable conditions, the UV C radiation inactivates the microorganisms in the water in such a way that they can no longer reproduce and die. Since this is a physical process, no chemical by-products or by-products hazardous to health arise during UV treatment. Ultrasound can be used to improve the effect further.

UV treatment for drinking water treatment

A requirement for UV treatment is water free of turbidity and a low microbial load. UV treatment is only effective during the radiation time, i.e. does not have an enduring effect in the net. UV systems are often used as the last stage in a treatment chain for final hygiene processing. Only tested and certified systems with a minimum dose of 400 J/m² may be used. If several systems are operated in parallel, the flow rate must be measured and, if necessary, controlled.