Filtration for Water Treatment

Filtration is one of the most important processes in water treatment and is used in a wide range of applications. It is a mechanical separation method in which solid or dissolved substances are removed from a liquid mixture, resulting in a purified filtrate and a concentrated retentate or concentrate.

The selection of a suitable filtration method—often involving multiple stages—depends on the composition of the raw water and the required quality of the treated water, such as drinking or process water. Filtration processes also include those using adsorptive filter media (e.g. activated carbon) or reactive materials (e.g. chemical deacidification).

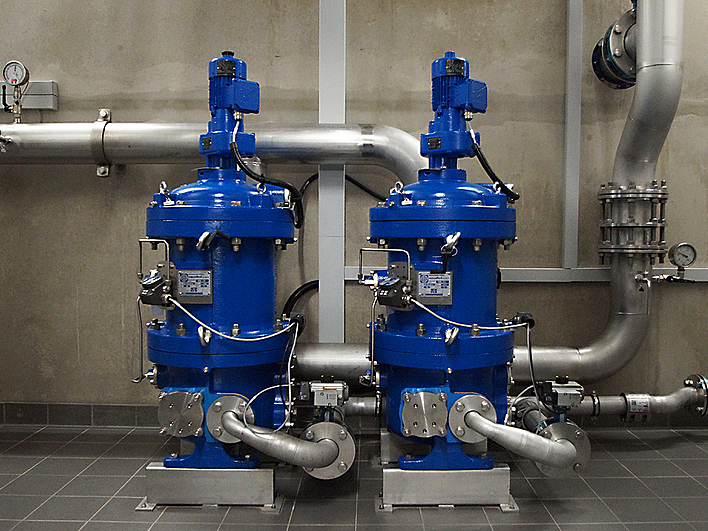

Screen filtration

Screen filtration is a reliable method for removing both coarse and fine solids from water. The water to be treated passes through a screen with a defined mesh size, which effectively retains particles such as sand, leaves, plastic debris, and other suspended matter. The screen acts as a physical barrier, allowing only particles smaller than the mesh size to pass through.

As the particle load increases, so does the pressure drop across the filter. For this reason, screen filters are typically operated as automatic backwash filters under higher load conditions. Backwashing is carried out in sections, allowing filtration to continue uninterrupted.

Screen filters are valued for their simple design, high efficiency, and dependable performance in pre-treatment applications within water treatment systems.

Fine filtration

Drinking water from extended municipal supply networks may contain contaminants such as rust, sand, loosened deposits, and other solid particles. These can be effectively removed using cartridge filters. However, cartridge filters are not designed to handle large volumes of particulate matter. When high dirt loads are present, solids quickly accumulate on the filter surface, leading to a rapid increase in differential pressure which requires replacement of the filter cartridges.

Fine filtration is also used upstream of nanofiltration and reverse osmosis systems. In these applications, fine filters protect membrane elements from fouling and extend their service life, ensuring consistent system performance.

Particle filtration

Depending on the application, gravel filters, sand filters, or multi-layer filters are used for particle filtration. Unlike cartridge filtration, particle filtration—especially multi-layer filtration (e.g., using filter sand and activated carbon)—is a form of depth filtration.

In multi-layer filtration, water flows through several layers of filter media, with increasing fineness in the direction of flow. Particles are retained at different depths within the filter bed based on their size. This allows multi-layer filters to capture large volumes of solids.

Gravel or multi-layer filters are commonly used in combination with a flocculation stage, particularly in the treatment of river water. In such cases, a sedimentation stage is typically implemented as the first treatment step. Both gravel and multi-layer filters are cleaned regularly by backwashing.

Open filter systems are rarely used today. Closed pressure filter systems—capable of operating at higher differential pressures—have become the standard.

Ozone bio-filtration

Ozone biofiltration is a combined process for water treatment in which ozonation (oxidative pretreatment) and biofiltration (biological degradation) are used in series. It is a process based on natural processes for the treatment of humic-containing water. The process uses biological mechanisms to reduce TOC/DOC in the filter bed. Further details on ozone biofiltration are described here.

Membrane filtration techniques

Membrane filtration techniques play a central role in modern water treatment. They are based on physical separation processes in which membranes act as filters. The various processes differ primarily in the pore size (selectivity) of the respective membrane. Membrane filtration includes the following processes:

- Microfiltration (MF) removes particles, bacteria, suspended solids, often used for pretreatment

- Pore size: approx. 0.1–1 µm

- Operating pressure: low (0.1–2 bar)

- Ultrafiltration (UF), removes viruses, colloidal substances, macromolecules (e.g., proteins)

- Pore size: approx. 0.01–0.1 µm

- Operating pressure: low to medium (1–5 bar)

- Nanofiltration (NF) removes divalent ions, pesticides, organic molecules

- Pore size: approx. 1–10 nm

- Operating pressure: medium (4–30 bar)

- Reverse osmosis (UO/RO) removes monovalent and divalent ions, salts, dissolved organic substances

- Pore size: < 1 nm (practically impermeable to dissolved substances)

- Operating pressure: high (50–80 bar)

Separation limits at a glance

| Process | Pore size | Retention capacity |

|---|---|---|

| Microfiltration | 0.1–1 µm | Bacteria, suspended solids |

| Ultrafiltration | 0.01–0.1 | Viruses, colloids, macromolecules |

| Nanofiltration | 1–10 nm | Hardness components, organic substances |

| Reverse osmosis | < 1 nm | Salts, ions, almost all dissolved substances |

Examples of applications for filtration processes

- Screen filtration, fine filtration for separating sand, solids, turbidity, and particles, as well as loosened incrustations from pipes

- Particle filtration for removing particles, iron, manganese, and arsenic

- Chemical deacidification for removing aggressive carbonic acid

- Activated carbon filtration for removing pesticides (PBSM), chlorinated hydrocarbons (CKW), PFAS, etc.

- Filtration for removing impurities from recirculating water systems (e.g., condensate-steam cycle)