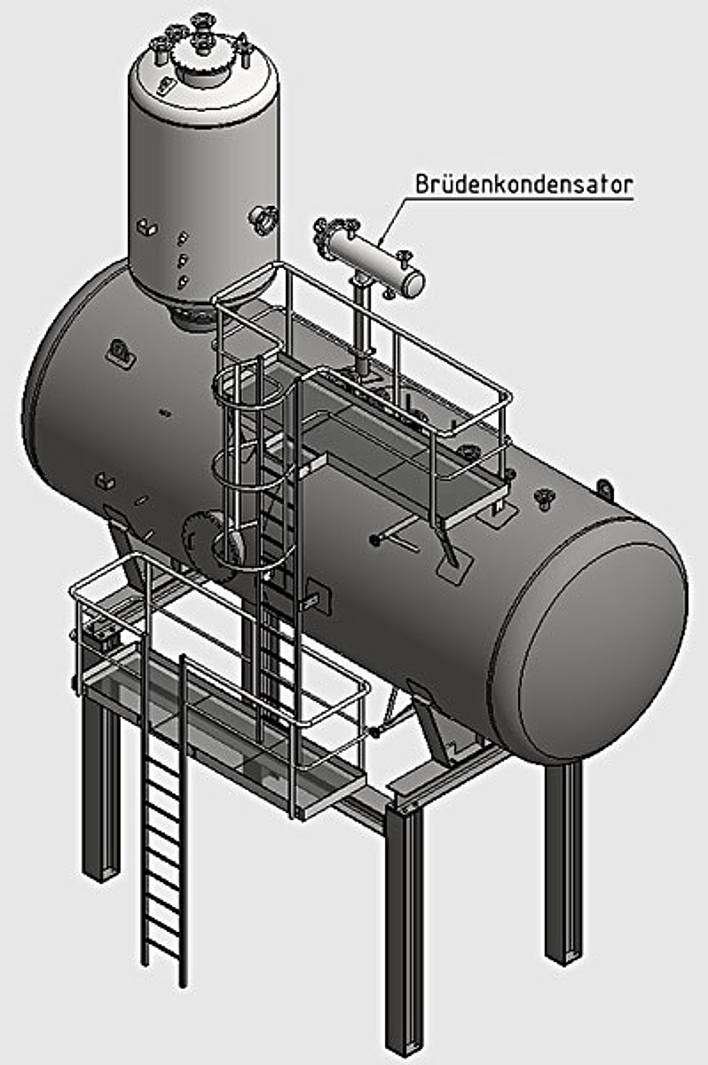

Thermal degassing system with steel substructure and exhaust vapour condenser

Our systems for thermal degassing (also pressure degassing) are complete performance units with optimally matched components. The systems are dimensioned so that an operating period of 20 to 30 minutes remains without supplementary water inlet when the feedwater tank is full.

A degassing system consists of several components:

- Degassing unit

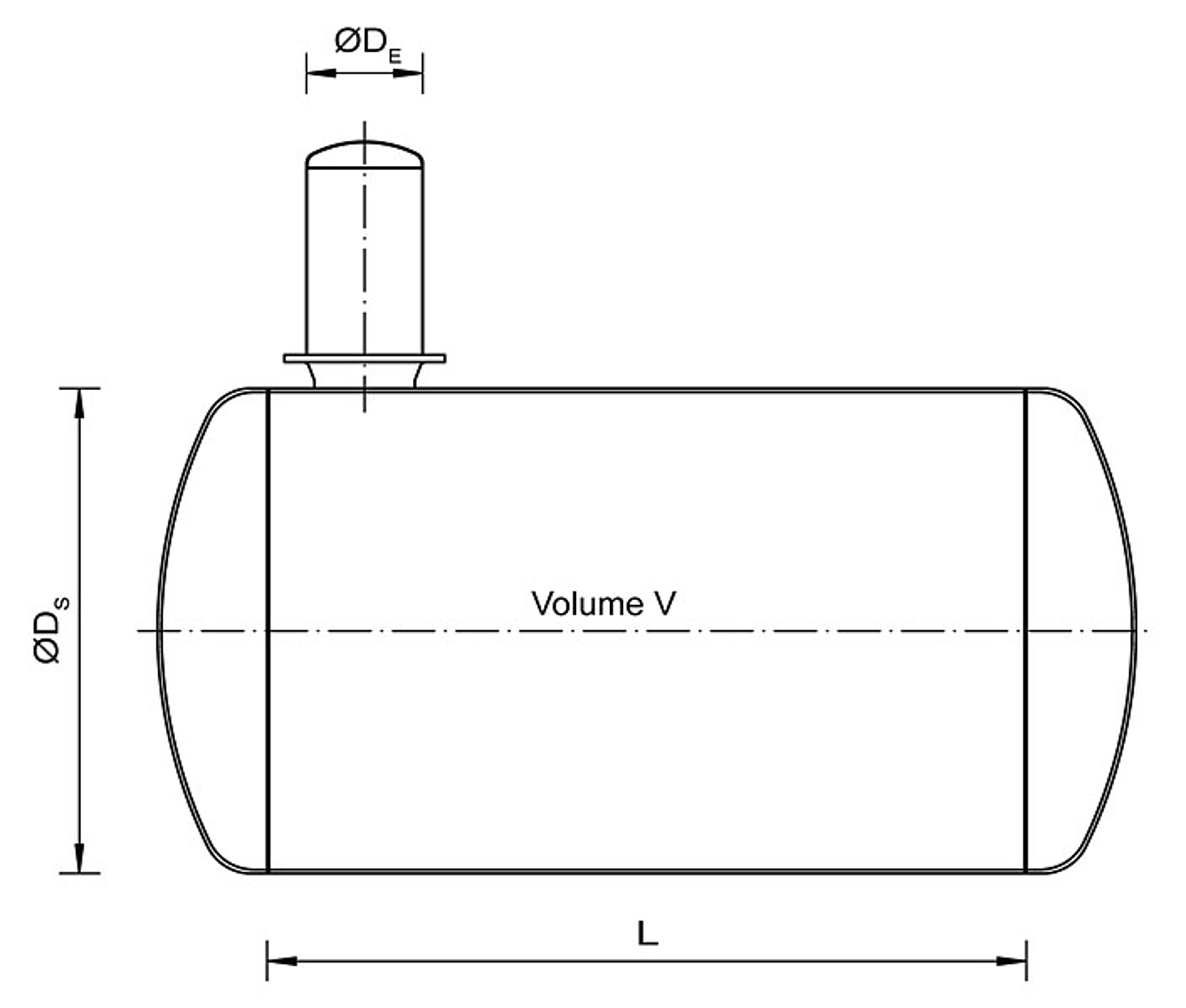

- Feedwater tank

- Instrumentation and control technology

- Steel structures, platforms and ladders

- Exhaust vapour condenser (optional)

- Safety devices and fittings

All systems are dimensioned and manufactured in accordance with the relevant regulations and subjected to a leak test and factory acceptance test (FAT).

Design

The performance units are designed for the following conditions:

- Feedwater: Approx. 105 °C and 0.2 bar overpressure

- Heating steam: Saturated steam with 180 °C and 9 bar overpressure

- Desalination rate: 3 %

- Exhaust vapour quantity: 0.3% of the rated output

- Condensate quantity: 50% of the rated output at 70 °C

- Supplementary water: 15 °C (43% share of the mass balance)

- Max. operating overpressure: 0.5 bar

- Max. operating temperature: 110°C

We also supply individual standardised degassing units up to 150 t/h, along with feedwater tanks, e.g. for substitution purposes. Special versions or versions that differ from the standard are available on request.

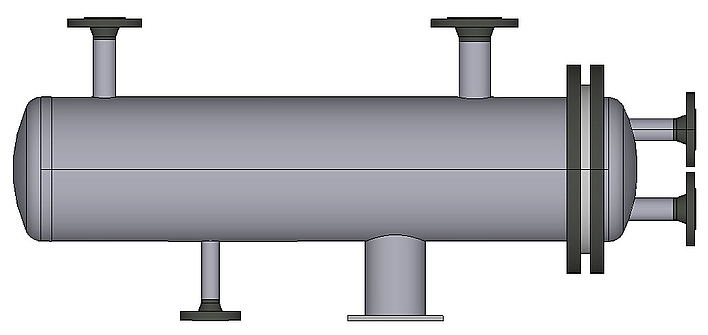

Exhaust vapour condenser

Tube bundle heat exchangers are normally used as exhaust vapour condensers. With these, the exhaust vapour is directed around the tube bundle while the water being heated flows through the tubes in the counter-current. Only stainless steel 316Ti is used as the material that comes into contact with the medium.

Exhaust vapour condensers should generally be individually planned and configured according to the operating conditions.